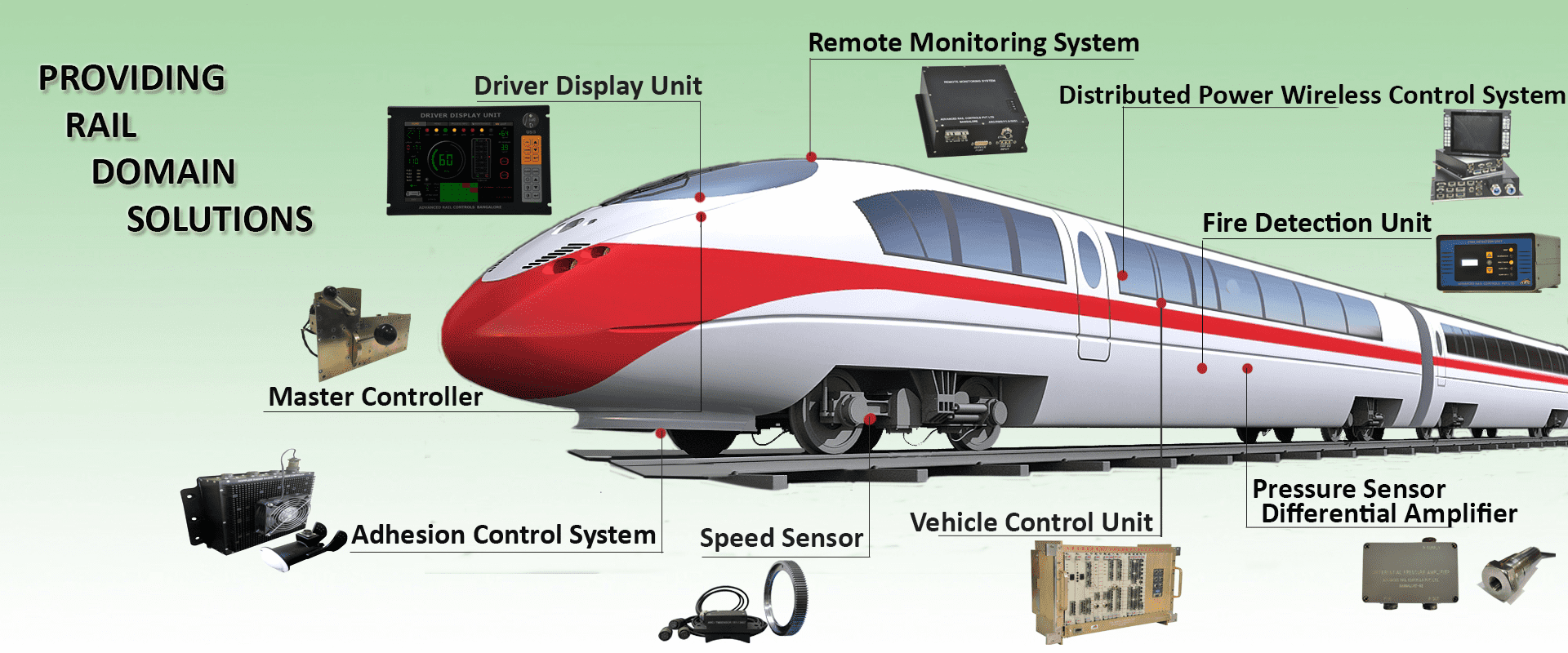

Advanced Rail Controls Pvt Ltd

“Driving Innovation in Locomotive Communication and Propulsion Technology.”

Advanced Rail Controls Private Limited is an ISO 9001:2015 certified Company established in 2005 in Bangalore (India) Engaged in the Design & Development of products and offering Services to Rail Transportation Sector, especially Rolling Stock.

Advanced Rail Controls Pvt Ltd is a prominent player in the propulsion technology sector, particularly in the domain of Indian Railways. The company was strategically acquired to expand into the locomotive segment, marking a significant step into a new domain. As a leader in manufacturing cutting-edge communication products essential for locomotive operations, Advanced Rail Controls Pvt Ltd has established itself as a key contributor to the efficiency and safety of railway services in India. Their innovative solutions play a crucial role in advancing the operational capabilities of the nation’s rail transport.

Products

LOCOMOTIVE DIAGNOSTIC SYSTEM

▪ Used in GTO Converter Based ABB LOCOS

▪ Connects to the MVB Network of LOCO

▪ Critical Tool needed for Production, Diagnosis, Fault Analysis

▪ Proprietary Tool

▪ Indigenously Developed & Import Substituted

DOPPLER RADAR BASED ADHESION CONTROL SYSTEM

▪ Interfaced with gto 3-phase locomotive as an add-on equipment interactingwith traction converter for re-adhesion control during wheel slip of freight locos at low speeds

TRACTION MOTOR SPEED SENSOR

▪ GTO CONVERTER FED LOCOMOTIVES

▪ Accepts 110V DC battery supply and Hall effect type active sensor.

▪ 100% signal compatibility with old Wiegand sensor (25us, 2.1V pulse)

▪ Output galvanically isolated.

▪ Bipolar Signal – Direction Encoded

REMOTE MONITORING & REMOTE DIAGNOSTICS SYSTEM

▪ Enables real time viewing of locomotive health over internet.

▪ Multiple pre defined screens for viewing, analysis and data refresh rate of 15 seconds.

▪ Sms alerts during fault and email alerts weekly.

DISTRIBUTED POWER WIRELESS CONTROL SYSTEM (DPWCS)

DISTRIBUTED POWER WIRELESS CONTROL SYSTEM (DPWCS)

▪ DPWCS is a technology to achieve very high freight throughput with very minimal input cost by way of heavy haul

▪ Many freight trains are combined as a single train and operated by a single crew in the lead master loco and all the slave locomotives are commanded through wireless

▪ As the locomotives (power) are distributed in a train and controlled through wireless, the name DPWCS emerged.

▪ Advanced Rail Controls Private Limited has done pioneering work in this field and became the first Indian company to develop and commercially deploy this technology in three phase locos of Indian Railways.

▪ Advanced Rail Controls Private Limited has already demonstrated the running of a 3 train combination having 177 loaded wagons with 6 numbers of distributed WAG9 locomotives of 6000 hp, named as Super Anaconda.

▪ Indian Railways has already decided to implement this technology in all modern three phase freight locomotives.

DPWCS FOR TAP-CHANGER BASED CONVENTIONAL DC DRIVE LOCOMOTIVES

DPWCS FOR TAP-CHANGER BASED CONVENTIONAL DC DRIVE LOCOMOTIVES

▪ Interfaced with gto 3-phase locomotive as an add-on equipment interactingwith traction converter for re-adhesion control during wheel slip of freightlocos at low speeds

POWER SUPPLY MODULES FOR TRACTION APPLICATION

Pressure Sensor Oil Circuit

Transformer & Differential Amplifier to Pressure Sensor Oil Circuit.

VEHICLE CONTROL UNIT (VCU) FOR LOCOMOTIVES

▪ IEC-61375 TCN Open architecture enables easy plug compatibility of 3rd party equipment like traction converter, auxiliary converter etc.

▪ Application developed in ‘C’ Language

▪ Redundancy: Even if one processor fails the other one will take care of the functionalities.

▪ Backward Compatibility with Legacy System

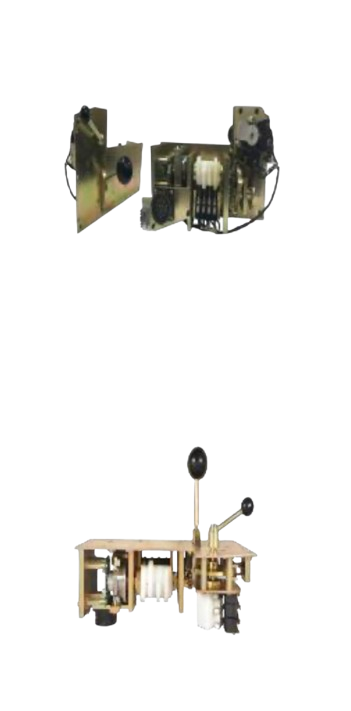

MASTER CONTROLLER

▪ Generates tractive and braking reference for VCU.

▪ Employs contact less angle encoder for angle detection.

▪ 4-20mA output signal.

▪ Integrated forward/reverse switch and CAM switches for sensing TE,BE,1/3

TE/BE and 2/3 TE/BE regions

PRINTED CIRCUIT BOARDS FUNCTIONALLY EQUIVALENT TO LEGACY SYSTEM IN GTO BASED LOCOMOTIVES – FOR

OBSOLESCENCE MANAGEMENT

PRINTED CIRCUIT BOARDS FUNCTIONALLY EQUIVALENT TO LEGACY SYSTEM IN GTO BASED LOCOMOTIVES – FOR

OBSOLESCENCE MANAGEMENT

▪ 100% Electrical, mechanical and functional compatibility (slot compatible) with legacy PCBS.

▪ Both Legacy cards and Equivalent cards can co-exist in the same rack.

▪ All obsolete electronic components eliminated.

▪ Component count reduced by combining the logics in CPLD which reduces power dissipation.

▪ Out of 26 types of cards we have completed 17 types of cards. 14 have been approved by RDSO for field validation

Clientele

Stay In Touch